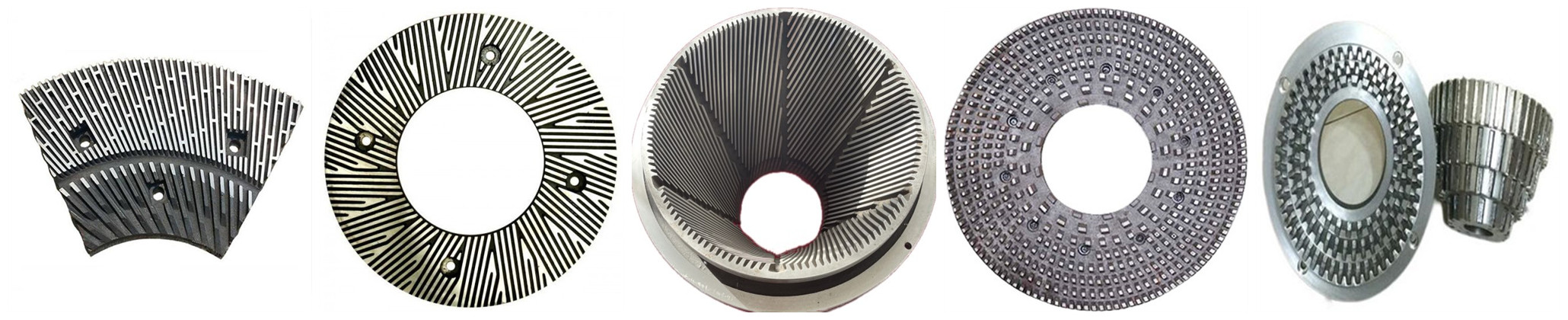

1. Design energy-saving refiner plates, optimize refiner plates pattern, increase refining production and reduce consumption.

2. Solve the problems of large grinding vibration, refiner plates plugging, fast wear problem of refiner plates, high power consumption,refiner plates rotor and stator eccentric grinding,refiner disc cavitation, refiner plates tooth surface grinding into serration, and refiner plates tooth breaking problem.

3.Solve the quality problems such as poor pulp decoupling, poor wet weight, poor cutting, poor silk brooming, and fiber failing to meet production requirements. The problem of pulp grinding into pulp agglomerates and grinding into ropes.

4.Solve the problems of coarse fibers, fine fibers, fiber discoloration, fiber grinding into powder and carbonization of tooth grooves, refiner plates steel grinding steel, and refiner plates fragmentation.

5. Research and development of special refiner plates for tobacco thin leaves.

6. Analysis of problems such as tooth shape selection, material selection, refining technology process, and mill operation.

7. Solve the problem of abnormal discharging of refiner plates due to refiner machine’s reasons (such as bending of mill main shaft, wear of spline, bearing clearance, etc.);

8. Solve the problem of pulp quality fluctuation caused by tooth passivation during refining (fiber grinding);

9. Solve the problem of high energy consumption, high cost and carbonization of Fiberboard (MDF & HDF) refiner plates during refining process.

Contact us to get a quotation now:

Tel: +86 17736903537( WhatsApp & Wechat)

Email: janet.wang@huataogroup.com

Related Products

Refiner Segments For Paper Making

Disperser Plate for Dispersion System

Degerm Mill Plate for Corn Starch Wet Milling

can not be empty

can not be empty