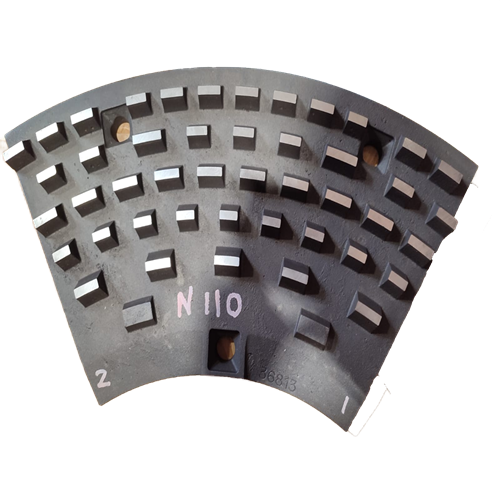

Material, high chromium alloy, alloy

Diameter of disc mill plates, 24'',36'',52''

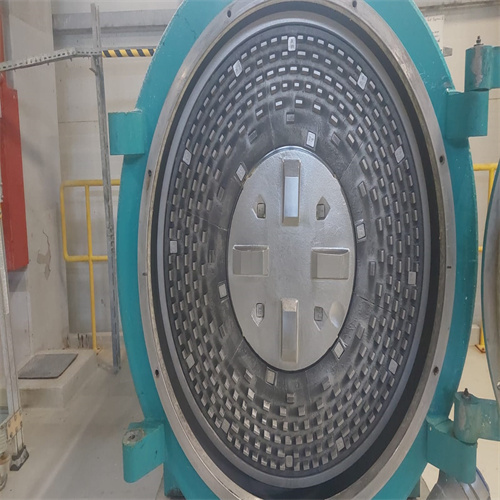

Corn starch degerm mill plates - core component of efficient grinding

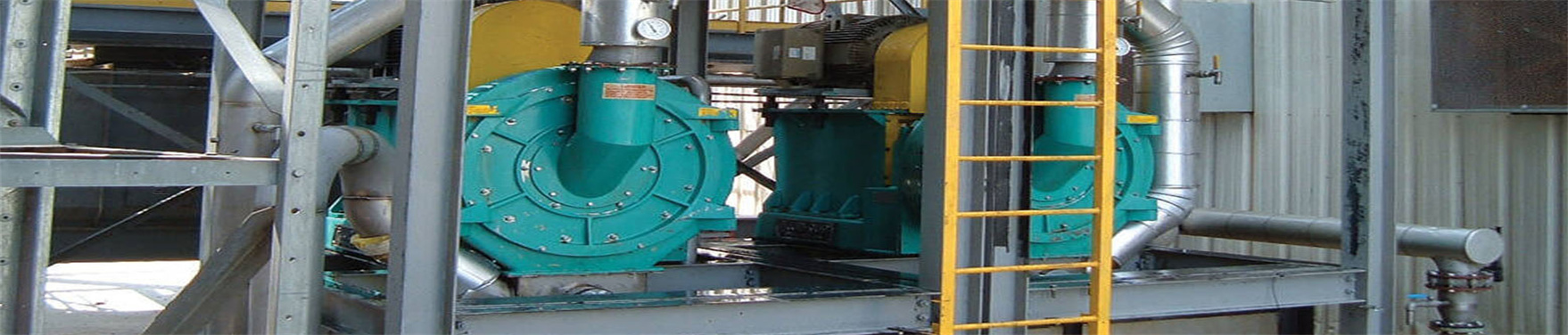

Corn starch degerm mill plates,also called disc mill plates, is the "core tooth" of Fluid-Quip corn processing mill, mainly used to crush corn particles and finely grind them into starch. It is made of high-strength wear-resistant materials and is suitable for corn starch production lines of various sizes. It can significantly improve grinding efficiency and starch extraction rate, and is an ideal choice for the starch processing industry.

Features

1.Wear-resistant construction

Adopting high-chromium alloy and other materials, impact-resistant and corrosion-resistant

2.High powder extraction rate

Optimized tooth shape design, larger grinding contact surface, more thorough corn crushing, starch extraction rate increased by 10%-15%, and reduced raw material waste.

3.Stable operation

Precise dynamic balancing treatment, high-speed operation without shaking, reduced equipment wear, uniform starch fineness, and stable finished product quality.

Technical Parameters

|

Material |

high chromium alloy, etc. |

|

Size |

24 inches, 36 inches, 52 inches |

|

Pattern |

Groove Patterns can be tailored. |

Application

Corn starch production: one-stop solution for coarse grinding and fine grinding

Choose our corn starch grinding disc, you will get:

Higher starch yield and quality

Longer service life

Lower maintenance cost