Capacity 6 t/d to 800 t/d

Diameter of refiner plates, 380mm to 1100mm

Consistency 3%-5%

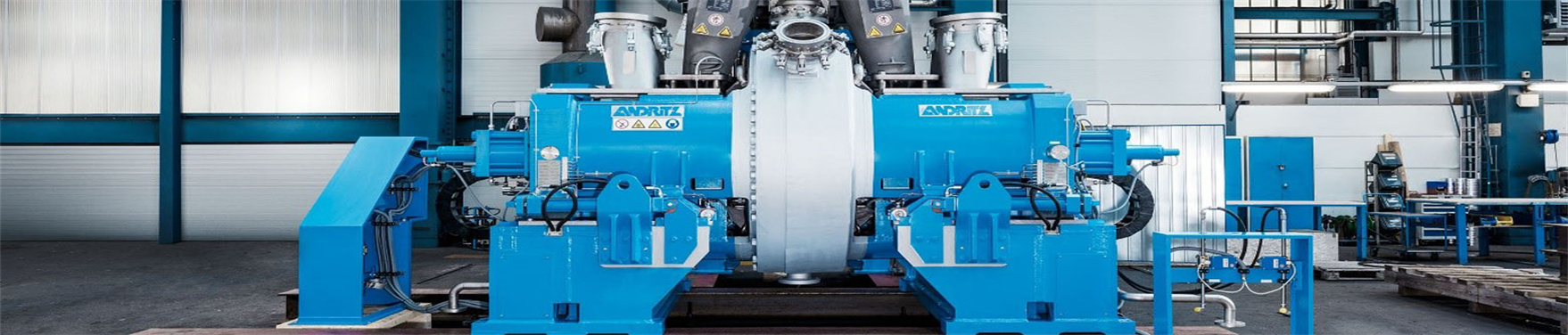

The double disc refiner is a critical machine in paper production, mechanically treating pulp fibers between two rotating discs. Its adjustable gap and pressure settings optimize fiber development for enhanced sheet formation. The robust design ensures consistent refining performance while minimizing energy consumption, making it ideal for various pulp grades and paper types.

Double Disc Refiner is suitable for continuous refining waste paper pulp, and wheat straw pulp, and suitable consistency is 2-5%.

Features

1.Higher refining efficiency

Dual discs working in opposition provide intense mechanical action, reducing energy waste while improving fiber development.

2.Precise adjustability

p and pressure control allow customized refining for different pulp grades, ensuring optimal paper strength and quality.

3.Uniform fiber treatment

Even distribution across the disc surfaces prevents over-processing and maintains consistency in pulp output.

4.Durable & Low Maintenance

Robust construction with wear-resistant materials extends service life and reduces downtime.

Application

1. Paper making machine DD Series Double Disc Refiner is mainly used for pulping, improving slurry beating degree to meet the paper making needs.

2. can be installed with a variety of tooth refiner plates. Suitable for various raw materials such as wood pulp, mechanical pulp, chemical pulp, waste paper pulp, etc.

3. Adopt a constant power control system, the beating effect is stable.

4. Accurate retract mechanism, easy to control, the beating effect is good

Technical Parameters

| Type | HT380 | HT450 | HT500 | HT550 | HT600 | HT660 | HT720 | HT900 | HT1100 |

| Diameter of refiner plate:mm | φ380 | φ450 | φ500 | φ550 | φ600 | φ660 | φ720 | φ900 | φ1100 |

| Capacity:t/d | 6-20 | 8-80 | 10-100 | 10-120 | 12-150 | 15-200 | 15-250 | 20-400 | 40-800 |

| Power of motor:KW | 37 | 90-160 | 132-200 | 160-250 | 185-315 | 220-355 | 250-630 | 315-800 | 400-1250 |

| Density:% | 3-5 | 3-5 | 3-5 | 3-5 | 3-5 | 3-5 | 3-5 | 3-5 | 3-5 |

Click directly to send a message via WhatsApp

Click directly to send a message via WhatsApp

can not be empty

The E-mail format is not correct

can not be empty