Diameter of refiner fillings: φ450-φ750

Capacity :20 t/d to 400 t/d

Density:3% - 5%

Conical degree: 40°

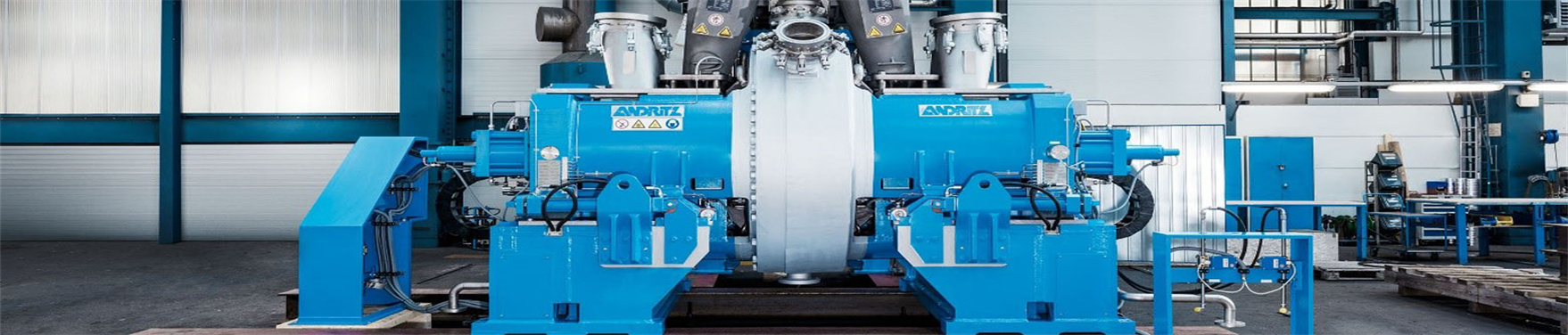

Conical Refiner is mainly used for coarse beating refining and re-pulping of broke and waster paper. It is available for long fiber pulp such as cotton, wood, and hemp. The equipment is furnished with an automatic control system and can beat with a constant power of constant energy consumption. The beating effect is stable.

Conical Refiner construction of Rotor and stator is conical.

Features

1.Conical Design

Features a tapered, cone-shaped refining zone that ensures gradual fiber treatment, improving fibrillation and reducing energy consumption.

2.Adjustable Refining Intensity

Allows precise control over refining pressure, gap, and speed to optimize fiber quality for different pulp types.

3.Durable Refining Plates

Equipped with hardened metal or composite plates with specialized patterns to enhance fiber cutting and brushing.

4.Energy Efficiency

Designed to operate at lower energy levels compared to disc refiners while maintaining high refining consistency.

Related Refiner Equipment:

Refiner, Double Dis Refiner, Conical Refiner, Claflin Conical Refiner, High Consistency Refiner

Technical Parameters

|

Type |

HT-450 |

HT-460 |

HT-600 |

HT-750 |

|

Diameter of refiner fillings: mm |

φ450 |

φ460 |

φ600 |

φ750 |

|

Capacity: t/d |

20-60 |

30-150 |

50-250 |

80-400 |

|

Power of motor: kw |

110-132 |

160-315 |

355-500 |

450-900 |

|

Density (%) |

3 - 5 |

3 - 5 |

3 - 5 |

3 - 5 |

|

Conical degree ° |

40 |

40 |

40 |

40 |

Click directly to send a message via WhatsApp

Click directly to send a message via WhatsApp

can not be empty

The E-mail format is not correct

can not be empty