Disperser Plate is the core component of Disc heat disperser system in the paper industry.

It is mainly used to treat sticky impurities and ink particles in waste paper pulp.

Through the heat generated by high-speed rotation and friction, the disperser discs can effectively disperse and peel off these impurities, thereby improving the whiteness of the pulp and the quality of the paper.

Features

Technical Parameters

|

Item |

Description |

|

Material |

Alloy with hardness 50-55HRC or 17-4PH with hardness 37-42HRC |

|

Suitable disperser model |

Cellwood KD450, KD710, KD1050, KD1250. |

|

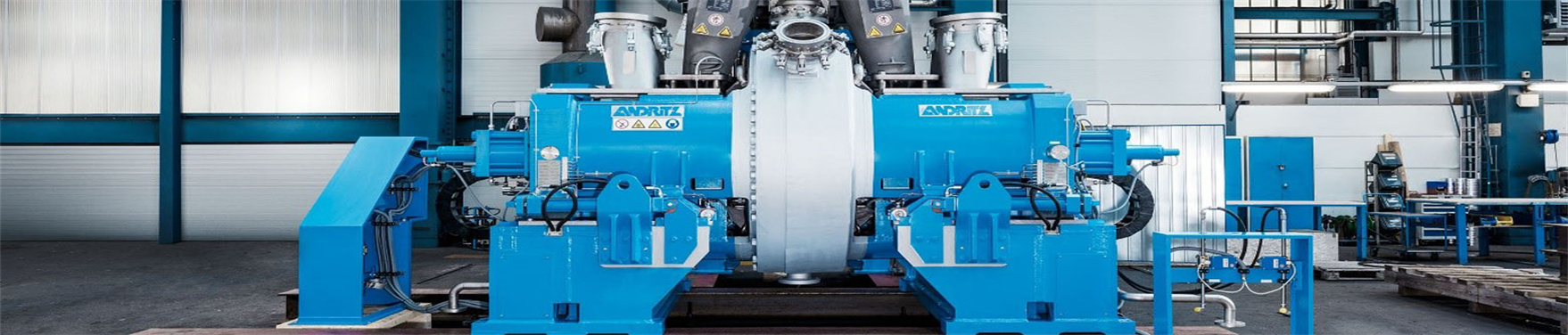

ANDRITZ CompaDis disperser |

CDI0,CDI1,CDI2,CDI3,CDI4,CDI5. |

|

Other Disperser Brand |

Kadant |

|

Diameter Range |

450mm-1610mm |

|

Working temperature |

80-120 ℃ |

|

Slurry consistency |

3% -6% |

|

Lifetime |

5000 hours to 10000 hours |

Application

Disperser plate are widely used in waste paper recycling, deinking production lines and the production process of high-purity pulp.

It is especially suitable for processing waste paper pulp containing a large amount of viscous impurities and ink.

It can significantly improve the whiteness and strength of the pulp and is suitable for the production of high-end cultural paper, packaging paper and special paper.

Click directly to send a message via WhatsApp

Click directly to send a message via WhatsApp

can not be empty

The E-mail format is not correct

can not be empty