Material G4-2,Precipitation Hardening Stainless Steel,Alloy

Deflaker Model Andritz,Valmet ,Parason and Others

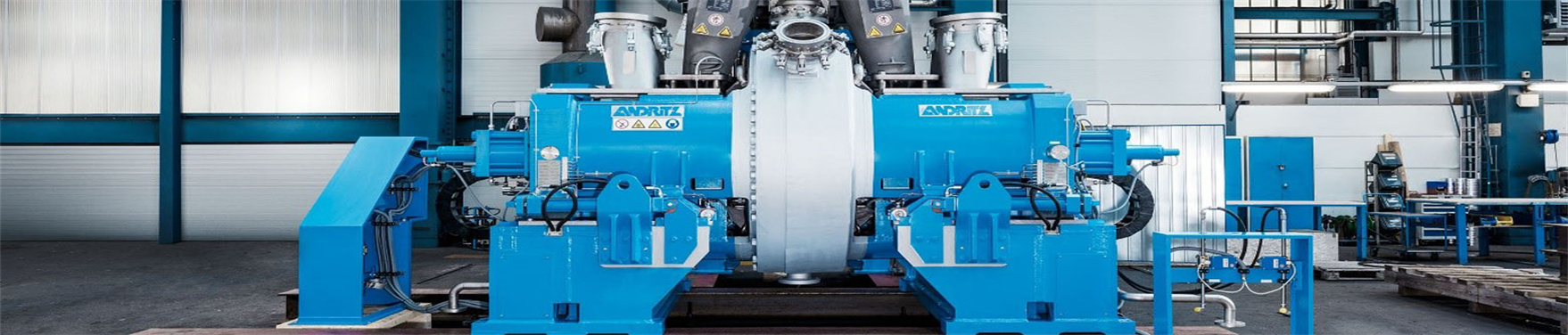

Over View

Huatao deflaker plate are instrumental in maintaining production efficiency. The precision engineering of these discs ensures consistent and uniform deflaking, leading to a more streamlined manufacturing process. This not only improves productivity but also reduces material waste, contributing to cost savings and overall operational efficiency.It is important to note that the selection of the appropriate fiber deflaker grinding disc is paramount in achieving optimal results. Factors such as disc material, design, and compatibility with deflaking equipment can significantly impact the deflaking process and the quality of the pulp fiber.

Features

One of the key advantages of using fiber deflaker plate is their ability to optimize the deflaking process, resulting in improved fiber dispersion within the slurry. This, in turn, contributes to the overall homogeneity and strength of the paper sheet. The deflaker plates are designed to withstand the abrasive nature of the deflaking process, offering exceptional durability and longevity in high-demand production environments.

Furthermore, fiber deflaker plates play a significant role in minimizing fiber damage during the deflaking process. By utilizing advanced grinding technologies, these discs can effectively separate fibers without causing excessive breakage or degradation. This is crucial in preserving the quality of the fibers, ultimately leading to the production of high-performance paper sheet with enhanced mechanical properties.

Technical Parameters

|

Item |

Description |

|

Material |

G4-2,Precipitation Hardening Stainless Steel,Alloy |

|

Deflaker Model |

Parason,Andritz,Valmet and Others |

Click directly to send a message via WhatsApp

Click directly to send a message via WhatsApp

can not be empty

The E-mail format is not correct

can not be empty