| Industries we serve | |

MDF Refiner Defibrator A wood fiber refiner, also known as a defibrator, is a machine used in the pulp and paper industry to refine wood chips or other raw materials into wood pulp. This process involves mechanically breaking down the wood fibers to produce a pulp suitable for papermaking or other applications. The wood fiber refiner typically consists of a rotating disk or drum with sharp blades or bars that shred and defibrate the wood chips. As the wood chips pass through the refiner, they are subjected to intense mechanical forces, which break them down into smaller fibers and fibrils. This refining action helps to increase the surface area of the fibers, improve their bonding properties, and enhance the quality of the pulp. Wood fiber refiners are essential equipment in pulp and paper mills, as they play a critical role in determining the quality and characteristics of the final paper product. Manufacturers design these machines to handle various types of wood chips and to achieve specific refining goals, such as pulp brightness, strength, and uniformity. Read More .jpg) Convex-teeth Corn Germ Stripping Mill Huatao degerming mill is a convex tooth-shaped crushing equipment used for wet production of corn starch. It is mainly used to crush soaked corn kernels and is used in conjunction with the germ cyclone to separate the germ and endosperm for subsequent production. In order to improve the yield of germs, secondary crushing and secondary separation processes are generally used, and the spacing between the moving plate and the fixed plate is adjusted to reduce the breakage rate of the germs. This equipment can also be used for coarse crushing of soaked soybeans in soybean product factories. Read More  Fiber Cement Board Refiner The multifunctional and efficient refining and desanding machine is mainly used in the papermaking industry (bleaching) for continuous refining of purified slurry or for homogenizing and refining waste paper regenerated slurry after deflaking. It is also used in the fiber cement board production industry. After treatment, the tensile strength, bursting strength, bonding strength and beating degree of the fiber can be improved. The pulp processed by this machine can obtain better tensile strength, folding resistance, and better combination of stiffness and air permeability. This machine can be used with double disc mills in series for refining, with conical mills for refining in series, or as a stand-alone machine. Read More |

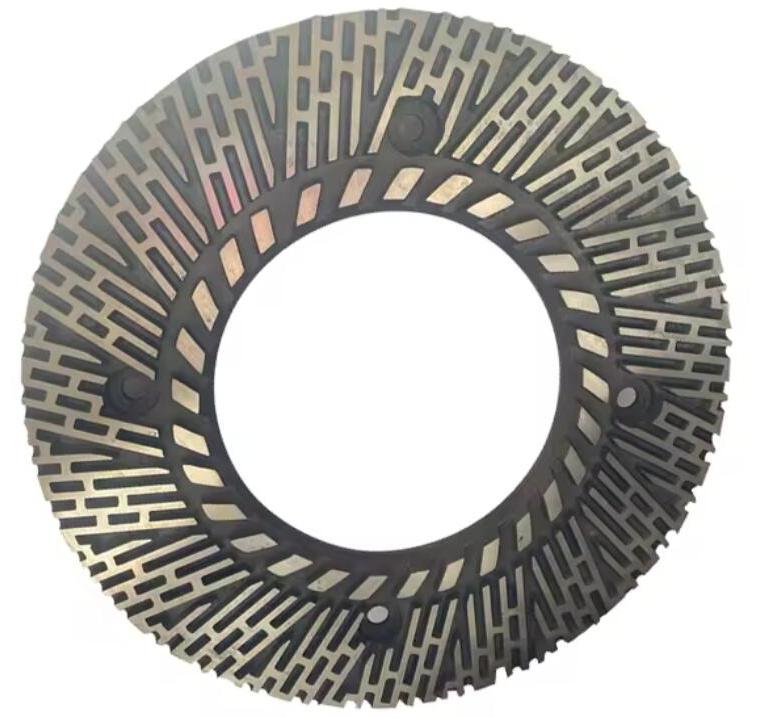

MDF Disc MDF (Medium Density Fiberboard) refiner discs are tools used in the wood processing industry for refining and grinding wood fibers to produce MDF. MDF is a type of engineered wood product made by breaking down wood fibers and combining them with resin adhesive under heat and pressure. The refiner discs play a crucial role in the MDF manufacturing process by ensuring the uniformity and quality of the wood fibers. These discs typically have sharp edges or teeth that shred and refine the wood fibers, resulting in a smoother and more consistent material for the production of MDF panels. Read More  Convex-Tooth Corn Degerminator Rotator The degerming mill rotator is a crucial component in the corn starch processing machine, specifically in the degermination stage. This innovative equipment is designed to efficiently remove the germ from corn kernels, ensuring the production of high-quality corn starch. With its advanced technology and precision engineering, the degerming mill rotator plays a pivotal role in enhancing the overall efficiency and productivity of the corn starch processing process. The degerming mill rotator operates by rotating the corn kernels against a stationary surface, effectively grinding and separating the germ from the endosperm. This mechanical action is essential for achieving the desired level of degermination without compromising the integrity of the starch granules. The precision and consistency of the rotator’s performance contribute to the overall reliability and effectiveness of the corn starch processing machine. Reade More .jpg) Fiber Deflaker Grinding Disc The production of fiber cement board involves several key processes, one of which is fiber deflaking. This crucial step involves the separation of fibers to ensure the uniform distribution of fibers within the cement matrix, ultimately impacting the board’s strength and quality. To achieve efficient fiber deflaking, the use of high-quality grinding discs is essential. Huatao fiber deflaker grinding discs are specifically designed to handle the demanding task of deflaking fibers in the production of fiber cement board. These discs are engineered to deliver precision grinding, ensuring the effective separation of fibers while maintaining their integrity. The use of fiber deflaker grinding discs is crucial in achieving the desired fiber length and distribution, which directly impacts the strength and performance of the final fiber cement board product. Read More  |

Office:

Tel:+86-311-80690567 , Fax:+86-311-68008382

Office:

Tel:+86-311-80690567 , Fax:+86-311-68008382 Website:

www.huataogroup.com

Website:

www.huataogroup.com